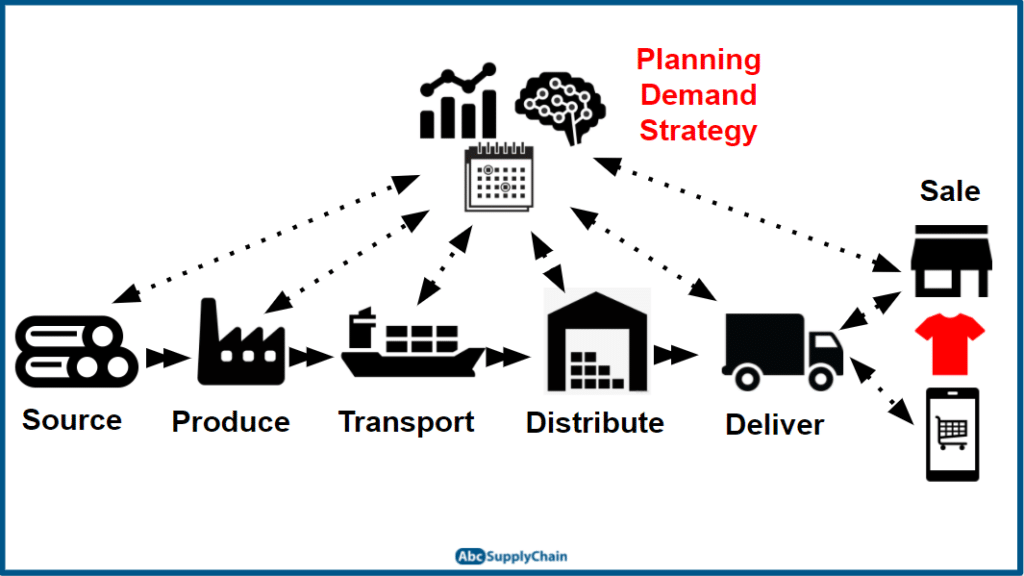

Supply chain management (SCM) is a critical aspect of business operations that involves managing the flow of goods, data, and finances from the procurement of raw materials to the delivery of the final product to the customer. While many people tend to associate supply chain management with logistics, it encompasses a much broader scope. In today’s digitally-driven world, SCM systems include material handling and software solutions that facilitate collaboration and information tracking among all parties involved in the creation, fulfillment, and delivery of products or services.

History of Supply Chain Management

Supply chains have been in existence since ancient times, starting with the very first product or service created and sold. However, with the advent of industrialization, supply chain management became more sophisticated, enabling companies to produce and deliver goods and services more efficiently. One significant milestone in SCM was Henry Ford’s standardization of automobile parts, which revolutionized mass production to meet growing customer demands. Over time, incremental changes and technological advancements, such as the invention of computers, have further enhanced SCM systems. However, until recently, SCM was primarily a linear and siloed function managed by supply chain specialists.

The Evolving Supply Chain Landscape

The internet, technological innovation, and the rise of the global economy have transformed the traditional supply chain into a complex and interconnected network. Today’s supply chain is no longer linear but rather consists of disparate networks accessible 24/7. At the heart of these networks are customers who expect their orders to be fulfilled promptly and accurately. As a result, effective supply chain management has become crucial for business success. Companies that can adapt their supply chains to the volatile and technology-driven business environment will thrive in the modern marketplace.

Industry 4.0 and SCM

The application of cutting-edge technologies to manufacturing, often referred to as Industry 4.0 or the “fourth industrial revolution,” has had a significant impact on supply chain management. Technologies such as artificial intelligence (AI), machine learning, the Internet of Things (IoT), automation, and sensors are transforming how companies manufacture, maintain, and distribute products and services. Industry 4.0 has fundamentally changed the way technology is integrated into the supply chain, enabling predictive maintenance and smarter decision-making processes. By leveraging technology, SCM systems can make the entire supply chain and the enterprise itself more intelligent and efficient.

The Customer-Centric SCM Approach

In the past, SCM primarily focused on increasing efficiency and reducing costs. However, today’s SCM prioritizes the customer experience and responsiveness. It has been rightly said that “customer experiences live and die in the supply chain.” Customer loyalty is built on an enterprise’s ability to fulfill customer expectations swiftly and accurately. To achieve this, companies must view their supply chains from the customer’s perspective. It’s not just about delivering the order on time; it’s about ensuring every step of the process, from procurement to logistics, is optimized to meet customer needs.

The Importance of Supply Chain Agility

Modern supply chains are broad, deep, and continuously evolving, requiring agility to be effective. In the past, supply chains followed a linear model that was unaffected by change. However, today’s consumers have multiple purchasing options and expect increasing levels of customization. An agile supply chain can meet these expectations by quickly adapting to changing circumstances, such as geopolitical and economic developments that impact sourcing. The ability to rapidly reconfigure the supply chain is essential to address unforeseen challenges. Furthermore, an intelligent SCM system should be able to mitigate the impacts of changing regulatory requirements, ensuring compliance while maximizing efficiency and reducing costs.

Leveraging the Cloud in SCM

The cloud offers numerous advantages when integrated into SCM systems. Cloud-based applications provide flexibility and adaptability to changing circumstances, making it easier to respond to unexpected sourcing issues or market fluctuations. Retrofitting legacy applications to accommodate new technologies can be complicated and expensive, whereas cloud solutions are inherently designed to make the most of emerging technologies. Additionally, cloud-based SCM allows for selective adoption based on specific business needs, without requiring a complete migration. This approach enables companies to extract more value from existing assets while customizing their cloud integration to suit their SCM requirements.

The Role of Blockchain in SCM

Visibility and traceability are critical in supply chain management. Blockchain technology offers a solution by enhancing transparency, traceability, repudiation, and trust throughout the supply network. The food industry, in particular, has benefited from blockchain implementation in SCM, enabling increased visibility, accurate forecasting, and deeper trust between companies and their customers. By incorporating blockchain into SCM processes, companies can ensure end-to-end visibility and build a network based on trust and accountability.

The Future of SCM

The future of supply chain management lies in network-based responsiveness and customer experience. Each node of the supply chain network must be flexible, attuned to customer needs, and capable of addressing various factors, such as sourcing, trade policies, and shipment modes. Advanced technologies, including AI and IoT, will play an increasingly significant role in improving transparency, visibility, and connectivity throughout the supply chain network. SCM planning will become a continuous process, with tighter alignment between planning and execution. Speed and accuracy will be essential to meet the challenges posed by evolving customer expectations, shorter product lifecycles, and fluctuating demand.

Oracle’s Intelligent SCM Solutions

To address the rapidly changing landscape of supply chain management, Oracle offers intelligent, cloud-based SCM solutions. These end-to-end product suites empower businesses to manage and optimize their supply chains as a complete ecosystem. With 100% visibility across the supply chain, companies can meet the challenges of increased customer expectations, shorter product lifecycles, and fluctuating demand. Oracle’s SCM solutions enable businesses to stay on the leading edge of supply chain management by leveraging advanced technologies and providing the agility and responsiveness required to succeed in today’s business environment.

Conclusion

Supply chain management plays a vital role in the success of businesses across industries. From procurement to order management, SCM encompasses a wide range of activities that must be optimized to meet customer expectations and adapt to changing market conditions. Industry 4.0 technologies, customer-centric approaches, supply chain agility, cloud integration, and blockchain implementation are key elements shaping the future of SCM. By leveraging intelligent SCM solutions, companies can stay ahead in the dynamic business landscape, ensuring efficient operations, customer satisfaction, and business growth. Embracing the power of technology and innovation is crucial for success in the ever-evolving world of supply chain management.